FOCUS ON TUNGSTEN CARBIDE PRODUCTS DEVELOPMENT/MANUFACTURE/PROCESS

| Availability: | |

|---|---|

| Quantity: | |

JDDF14

Jinding

Product Description

Quick Detail

Product name: Zhuzhou YG6 Cemented Carbide Sandblasting Fuel Spray Nozzle

Customized support: OEM and ODM

Material: 100% Virgin Tungsten Carbide

Grade: YG6, YG8, K10, K20, etc

Particle: Medium, fine and coarse

Size: Standrad or OEM accepted

Hardness: HRA89-HRA92.9

Color: Gray

Surface: Blanks or sintering / polishing

Usage: For Wear Parts

Product Application

Tungsten carbide nozzle, made of high grade tungsten carbide, is one of the spray nozzles. The hardness reached over HRA90 degree while the anti-bending degree reached over 2300N/mm.

Tungsten carbide nozzle mainly used for powdering , rust removal , cleaning atomizing in the field of chemistry , food , machinery ,architecture etc.

More than 800 sorts of products are available . With accurate dimension , fine atomizing particles and completely burning. All kind of atomizing plates can be used as optimized for oil burners,furnaces and other specially purposed heating furnaces.

They are used as optimized environment protection products for de-dusting and detergent in the factory with that seriously polluted.

Recommended Brand

Grade | Physical and mechanical properties | Applications recommended | ||

Density g/cm3 | Hardness No Less Than HRA(HV) | TRS No Less Than (Mpa) | ||

YG3 | 15.10~15.30 | 92.5 | 1700 | Superior wear resistance only less than YG3X, sensitive to impact and vibration, suitable for cast non-ferrous metal and its alloy finish turning, semi-finish turning, thread finish turning and hole expanding. |

YG3X | 15.10~15.30 | 93.6 | 1450 | Best wear resistance in Tungeten and Cobalt alooy, but not good in anti-impact proprety, suitable for cast iron, non-ferrous and alloy, quenched steel, alloy steel small cutting section machining at high speed. |

YG6 | 14.80~15.00 | 91.1 | 2100 | High wear resistance but less than YG3, better anti-impact and anti-vibration than YG3X, Suitable for cast iron, non-ferrous and alloy, non-metal material semi-finish machining and finish machining. |

YG6X | 14.80~15.00 | 92.4 | 2000 | Belong to small granule Tungsten carbide alloy, wear resistance higher than YG6. Suitable for machining cold and hard alloy cast iron and heat resistance alloy steel, as well as finish machiing for normal cast iron. |

YG8 | 14.6~14.80 | 90.5 | 2300 | High bending strength resistance, better anti-impact and anti-vibration than YG6, suitable for cast iron, non-ferrous and alloy, non-metal material rough machining at low speed. |

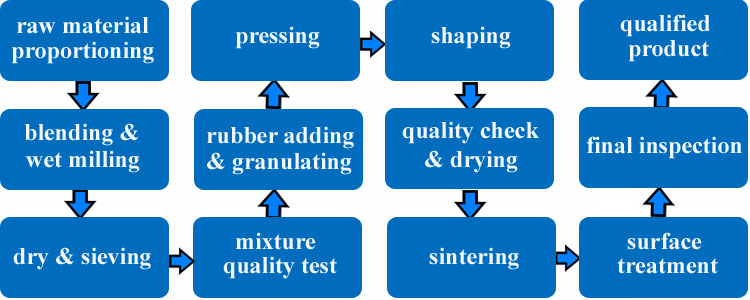

Production Process

Please leave message and we will get back to you ASAP!

Wechat : mayyang789