FOCUS ON TUNGSTEN CARBIDE PRODUCTS DEVELOPMENT/MANUFACTURE/PROCESS

| Availability: | |

|---|---|

| Quantity: | |

JDCD13

Jinding

Product Description

Product Detail

Product name: Tungsten Carbide Tips of Bush Hammer Rollers for Mable Stone Milling Grinding

Material: 100% tungsten carbide

Grade: YG6, YG8, YG11, YG13,YG15, YG6X, YG8X or custom grade as per request

Customized support: OEM or ODM

Shape and Size: Custom design

Surface treatment: Ground / grinding / polished

Feature: Stable properties and longer life time

Usage: For cutting stone milling, stone carving, stone grinding, stone decoration,etc

Application: Sandstones, tuffs, limestone, marble and so on.

Product Features

1. Our factory provide a wide range of brazing tungsten carbide soldering insert tips for both wood and metal cutting/ wood cutting applications.

2. Using dedicated mould tooling we produce a wide range of tungsten carbide tips for stone cutting, stone grinding, processing, etc.

3. We also offer alternative tungsten carbide grades for steel cutting and nail busting applications upon request.

4. Different types of ground/ grinding/ polished carbide inserts and blank/ unground tungsten carbide inserts/ tips for bush hammer bits are available, we can produce it as customers' request.

Product Application of Cemented Tungsten Carbide Tips for Bush Hammer Roller

1. Bush hammer carbide tips was brazed on litchi mill machine for percussion or chisel on the granite surface, in form a stone surfacesuch as litchi skin rough surfacegranite litchi surface more use in sidewalk surface or square floor and so on for anti- slip.

2. Bush hammer carbide tips has more hardness and abrasive resistance, especially at higher temperature, it still has higher hardness.

3. Bush hammer carbide tips has very high elastic modulus.

Recommended Brand

Grade | ISO grade | Density | Hardness | TRS |

(g/cm3) | (HRA) | (MPa) | ||

K20 | K20 | 14.9-15.0 | 90.5-91.5 | 1900-2300 |

K30 | K30 | 14.6-14.8 | 89.5-90.5 | 1900-2300 |

K40 | K40 | 14.5-14.8 | 89.0-90.0 | 2000-2400 |

YG20 | K30 | 14.6-14.8 | 88.4-89.2 | 2000-2500 |

YG15 | K40 | 14.4-14.6 | 87.5-88.5 | 2200-2600 |

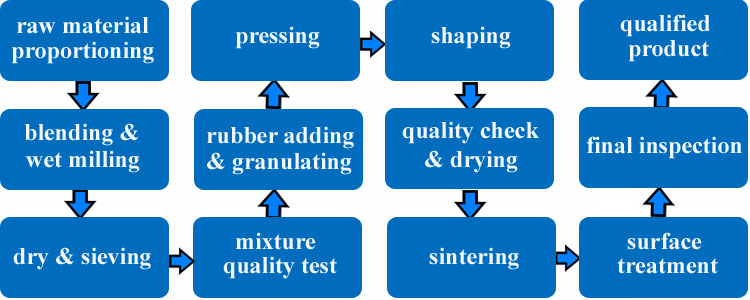

Production Process

Please leave message and we will get back to you ASAP!

Wechat : mayyang789