FOCUS ON TUNGSTEN CARBIDE PRODUCTS DEVELOPMENT/MANUFACTURE/PROCESS

| Availability: | |

|---|---|

| Quantity: | |

JDDH4

Jinding

Product Description

Quick Detail

Product name: Tungsten Carbide Tip For Surgical Needle Holder, Medical Needle Holder TC Inserts

Customized support: OEM and ODM

Material: 100% Virgin Tungsten Carbide

Grade: YG6 / YG6X / YG8, etc

Size: Standrad(15mm, 17mm, 20mm ) or OEM accepted

Color: Silver or Blank

Surface: Blanks or Polished / Grinding

Product Application

1. Tungsten Carbide Surgical forceps or needle holder forceps made of cemented carbide inserts on the head.

2. According to different purposes, there are many specifications and models.

3. It has good clamping performance and corrosion resistance.

4. It Mainly used for holding needles and sutures during surgery.

Recommended Brand

Grade | Physical and mechanical properties | Applications recommended | ||

Density g/cm3 | Hardness No Less Than HRA(HV) | TRS No Less Than (Mpa) | ||

YG6 | 14.80~15.00 | 91.1 | 2100 | High wear resistance but less than YG3, better anti-impact and anti-vibration than YG3X, Suitable for cast iron, non-ferrous and alloy, non-metal material semi-finish machining and finish machining. |

YG6X | 14.80~15.00 | 92.4 | 2000 | Belong to small granule Tungsten carbide alloy, wear resistance higher than YG6. Suitable for machining cold and hard alloy cast iron and heat resistance alloy steel, as well as finish machiing for normal cast iron. |

YG8 | 14.6~14.80 | 90.5 | 2300 | High bending strength resistance, better anti-impact and anti-vibration than YG6, suitable for cast iron, non-ferrous and alloy, non-metal material rough machining at low speed. |

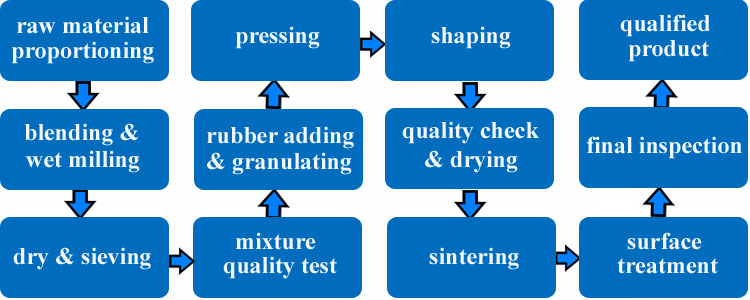

Production Process

Please leave message and we will get back to you ASAP!

Wechat : mayyang789