FOCUS ON TUNGSTEN CARBIDE PRODUCTS DEVELOPMENT/MANUFACTURE/PROCESS

| Availability: | |

|---|---|

| Quantity: | |

JDCA9

Jinding

Product Description

Product Detail

Product name: Tungsten CNC Turning Inserts Carbide Threaded Insert

Product Type: Carbide external turning insert

Customized support: OEM or ODM

Material: Tungsten carbide

Grade: YP731 for Stainless Steel Machining

Clearance Angle: A, B, C, D, E, F, G, N, P, O

Nose Radius: 0.2-3.2mm

Shape and Size: Standrad or OEM accepted

Surface finish: PVD/CVD, CVD, PVD, Double Coating

Machining: Finish,semi-Finish,roughing

Hole: With or without

Application: For cutting steel,stainless steel,cast iron,aluminum,and so on.

HS Code: 8208101900

Product Features

1. Good chip control & perfect turning surface

Provides perfect turning surface of the workpiece .Excellent and reasonable Chipbreaker design, removing the chips smoothly and taking away the heat of the rubs of the workpiece.

2. CVD coating ensures the high wear resistance

The layer of the CVD coating with the thickness around 8um-20um which guaranteed the high wear resistance.

3. Less tool breakage, cost down of each component

Saving costs and reducing the cost of each component to increase the profits .The high wear resistance makes the long tool life of the carbide inserts, which means you could saving more budget on purchasing the inserts.

4. Long tool life, higher production.

Long tool life means you need less time changing the inserts while machining. A reliable and safe performance every time.

1. Flank Wear

-Workpiece material contains high hardness chemical elements (tool steel, die steel)

Increase cutting speed if abnormal flank wear is caused by a very slow cutting speed.

Solution: Reduce cutting speed or feed rate or use more wear resistant grade

2. Crater Wear

-Workpiece material contains high hardness chemical elements

Solution: Reduce cutting speed or feed rate or use more wear resistant grade

3. Cracking

-Excessive feed rates when interrupted cutting

Solution: Reduce feed rate, Use tougher grade

1. Recommending more suitable processing parameters.

2. According to the workpiece design, material and CNC machine feed rate, cutting speed we can recommending a full set of practical scheme.

3. Suggsting more suitable model to replace the brands of Japan, Korea and so on.

4. We can offer together with tool holder.

Product Type

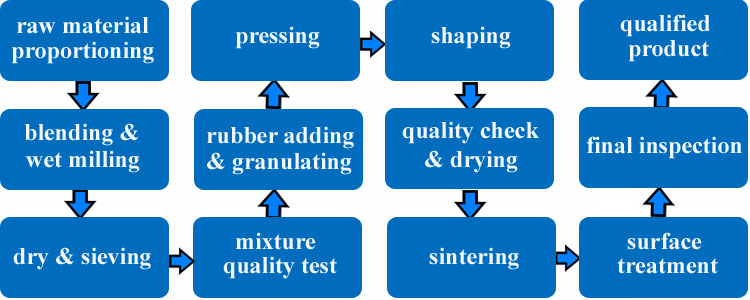

Production Process

Please leave message and we will get back to you ASAP!

Wechat : mayyang789