FOCUS ON TUNGSTEN CARBIDE PRODUCTS DEVELOPMENT/MANUFACTURE/PROCESS

| Availability: | |

|---|---|

| Quantity: | |

JDDF16

Jinding

Product Description

Product Features:

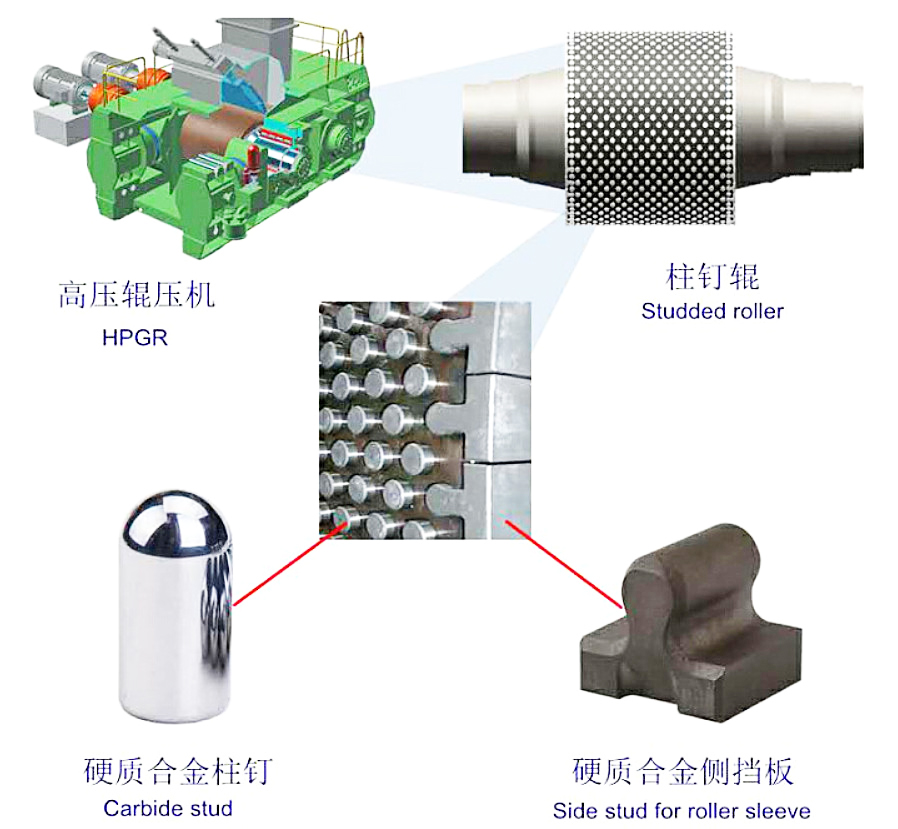

1. High Pressure Grinding Roller is an energy-efficient crushing equipment of new technologies.

2. High performance of carbide stud extends the life of High Pressure Grinding Roller.

3. We provide quality carbide stub with good wear resistance and high compressive strength, it can satisfy the requirements of different conditions.

Product Application:

1. Grinding bulk material.

2. As pre grinding equipment before ball mill or form complex grinding system with ball mill in the field of mineral separation.

3. It widely used in grinding cement clinker, limestone, bauxite, iron ore.

The method of installing the carbide stud is as follows:

1. Surfacing welding 2. Cold pressing 3. Hot inlay 4. Adhesive

With the advantages of high crushing efficiency, low energy consumption and high material yield, high-pressure roller press is gradually recognized by the market. The running status of the roller press is determined by the performance of the carbide roller press stud.

Recommended Brand:

| Grade | Density (g/cm3) | Hardness (HRA) | T.R.S (MPa) | Application recommended |

| YG6 | 14.95 | 90.5 | 1900 | For coring crowns,electric coal drill bits,coal cutting picks,oil cone bits and scraping knife bits,used in geological prospecting,coal mining and oil well boring. |

| YG8 | 14.8 | 89.8 | 2800 | Used as a core drill, electric coal drill, coal cutter tooth, oil roller bit and scraper button bit. |

| YG8C | 14.8 | 89.8 | 2800 | Mainly used for small and medium-sized drill bit tooth, and as a rotating exploration drill bush. |

| YG11C | 14.4 | 86.5 | 2700 | Most used in the drill bit and rock bit used for cutting high hardness materials ball tooth. |

| YG13C/YK40 | 14.2 | 86 | 2900 | mainly used for rotary drill bit used for cutting high hardness materials in ball mill. |

| YG15C | 14 | 85 | 3000 | Used in oil cone bit and soft in the hard rock digging cutting tools. |

| YK05 | 14.9 | 90.5 | 2600 | Mostly used as the buttons of small and mediumsized bits to cut soft and medium hard formations |

| YK15 | 14.6 | 88 | 2750 | Suitable to strips,conical buttons for rotary percussion-resistant geological prospecting buttons,cut soft and medium hard formations. |

| YK20 | 14.5 | 87.5 | 2800 | Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard and very hard formations, |

| YK25 | 14.4 | 87.2 | 2550 | Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard,hard,and very hard formations |

Production Process:

To ensure the quality and the requirements of the drawings can be met before mass production:

1. Start to prepare the RTP powder as per customer's requirement with our wet-grinding machine.

2. Before mass production, do a trial pressing and sintering using mould.

3. Check the appearances and the sizes of the samples with micrometer, projectors etc.

Test process of high lifetime Cemented Carbide button stud pins HPGR for breaking stones formations:

1. Mass production, press the raw materials to shape blanks.

Notes: all carbide stud pins blanks must be passed by semi finished inspection.

2. Sinter blanks to finish (HIP) and finished products inspection.

Notes:10 sets of vacuum sintering furnace and 2set of HIP in the factory ensure the best quality and production capacity.

3. Cleaning/tumbling to make the carbide stud pins clean and nice surface.

Please leave message and we will get back to you ASAP!

Wechat : mayyang789