FOCUS ON TUNGSTEN CARBIDE PRODUCTS DEVELOPMENT/MANUFACTURE/PROCESS

| Availability: | |

|---|---|

| Quantity: | |

JDAG2

Jinding

Product Description

Product Detail

Product name: High Precision Polished Tungsten Carbide Pin/Needle With High Hardness

Material: 100% Tungsten Carbide

Customized support: OEM and ODM

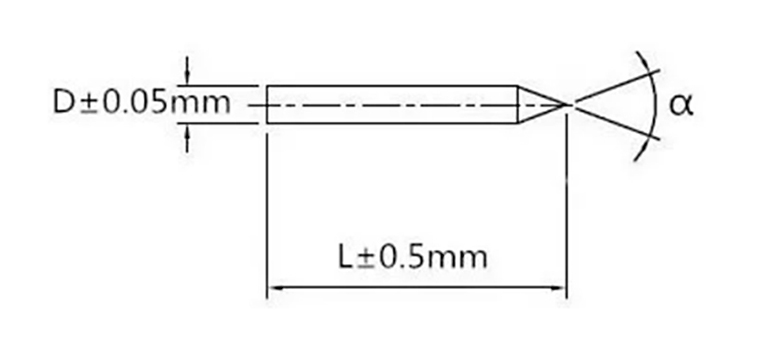

Size: φ3*18 or as customer's drawings

Size Tolerance: 0/+0.3 tolerance or as customer's request

Cutting Angle: 60°, 80°, 90°, etc

Recommend Grade: YG6, YG6X, YG8, YG10X, etc

Grain Size: Medium / Fine Grain

Usage: It mainly used for marking on metals, stones and wood.

Sintering Treatment: HIP sintering

Product Features: Long life, wear resistance

Product Application

1. Tungsten carbide pin is a composed of refractory alloys used in the instrument of super sharp electrode, said there is a blunt and sharp bottom electrode, the vertical axis of super large electrode cylindrical refractory alloy composition, and can change cycle cancellation and molten pool bar.

2. It often used for point tool, carving bits, rotary, scratch engraving, scribing, etching, and so on.

Product Specifications

Please check our molds as below.

For other sizes, we can also do custom design, it according to clients’ requirements or drawings.

| Item No | D | L | α |

| 1 | 1.5 | 8 | 30°/45°/60°/90° |

| 2 | 2 | 10 | 30°/45°/60°/90° |

| 3 | 2.5 | 20 | 30°/45°/60°/90° |

| 4 | 3 | 15 | 30°/45°/60°/90° |

| 5 | 4 | 14 | 30°/45°/60°/90° |

| 6 | 5 | 18 | 30°/45°/60°/90° |

| 7 | 6 | 20 | 30°/45°/60°/90° |

| 8 | 7 | 20 | 30°/45°/60°/90° |

| 9 | 8 | 22 | 30°/45°/60°/90° |

| 10 | 10 | 26 | 30°/45°/60°/90° |

Recommended Grade

| Grade | Density | T.R.S | Hardness | Performance & Application Recommended |

| g/cm3 | N/mm² | HRA | ||

| YG6 | 90 | ≥3000 | 14.9 | Good wear resistance,used for hard wood, used for processing original wood,aluminum section bar, brass rod and cast iron. |

| YG6X | 91.5 | ≥3500 | 14.9 | Has wear resistance higher than YG6,used for processing hard wood,original wood,aluminum section bar,brass rod and cast iron. |

| YG8 | 89.5 | ≥3200 | 14.7 | Wear and percussion resistance,used for processing hard wood,soft wood,ferrous and non-ferrous. |

| YG10X | 90 | ≥3650 | 14.4 | Wear resistance and strength comparatively higher,suitable for processing cast iron,non-ferrous,metal and non-metallid materials. |

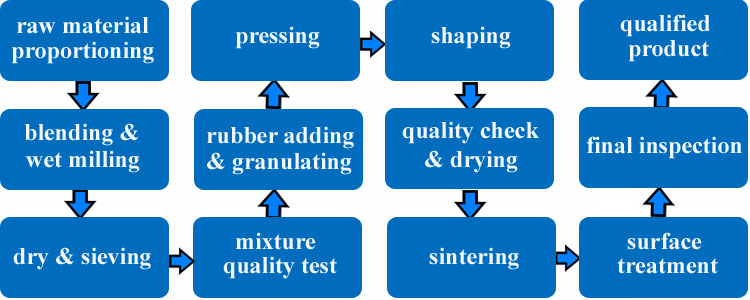

Production Process

About Us

Please leave message and we will get back to you ASAP!

Wechat : mayyang789