FOCUS ON TUNGSTEN CARBIDE PRODUCTS DEVELOPMENT/MANUFACTURE/PROCESS

| Availability: | |

|---|---|

| Quantity: | |

JDDE6

Jinding

Product Description

Quick Detail

Product name: High Hardness Solid Steel Grinding Media Balls For Ball Mill

Customized support: OEM and ODM

Business type: More than 16 years manufacturer

Material: 100% tungsten carbide

Grade: YG3,YG6,YG8,YG10,YG12,YG15,YG20,etc.

Feature: High durable, high accurate

Hardness: HRA85 - HRA92.9

Size: OEM accepted

Surface: Blanks or polished grinding

Main features

1. Tungsten carbide ball is mainly composed of high-hardness refractory metal carbide (WC, TiC) micron powder with cobalt (Co) or nickel (Ni), molybdenum (Mo) as binder in vacuum furnace or Sintered powder metallurgy products in hydrogen reduction furnace.

2. Tungsten carbide ball raw material : WC 94%, Co 6%. We can also provide other material as your request,such as: WC 92%, Co 8%; WC+Ni

3. Tungsten carbide ball has high hardness, wear resistance, corrosion resistance, bending resistance, and bad use environment, it's able to with stand hard shocks and impacts, and it can replace all steel ball products.

4. Tungsten carbide ball’s hardness ≥ 90.5, density = 14.9g/cm3.

5. Tungsten carbide balls common applications include ball valves, flow meters, ball bearings, linear bearings, tungsten carbide grinding balls, and ball screws, grinding, hardness examine machine, avigation , grinding machine, head pressure, and so on.

Product Specifications

Recommended Brand

| Grade | Density (g/cm3) | Typical Value | Application Scope | |

| Hardness | Bending Strength | |||

| YG3 | 15.10~15.30 | 92.5 | 1700 | Superior wear resistance only less than YG3X, sensitive to impact and vibration, suitable for cast non-ferrous metal and its alloy finish turning, semi-finish turning, thread finish turning and hole expanding. |

| YG3X | 15.10~15.30 | 93.6 | 1450 | Best wear resistance in Tungeten and Cobalt alooy, but not good in anti-impact proprety, suitable for cast iron, non-ferrous and alloy, quenched steel, alloy steel small cutting section machining at high speed. |

| YG6X | 14.80~15.00 | 92.4 | 2000 | Belong to small granule Tungsten carbide alloy, wear resistance higher than YG6. Suitable for machining cold and hard alloy cast iron and heat resistance alloy steel, as well as finish machiing for normal cast iron. |

| YG6 | 14.80~15.00 | 91.1 | 2100 | High wear resistance but less than YG3, better anti-impact and anti-vibration than YG3X, Suitable for cast iron, non-ferrous and alloy, non-metal material semi-finish machining and finish machining. |

| YG6A | 14.8~15.00 | 92.8 | 1850 | Belong to small granule alloy, wear resistance hig, suitable for semi-finish machining of cold and hard cast iron, non-ferrous and alloy, as well as semi-finish machining and finish machining for quenched steel, alloy steel |

| YG8 | 14.6~14.80 | 90.5 | 2300 | High bending strength resistance, better anti-impact and anti-vibration than YG6, suitable for cast iron, non-ferrous and alloy, non-metal material rough machining at low speed. |

| YG522 | 14.20~14.40 | 92.5 | 2000 | High wear resistance, and high strength, special grade for bamboo and wood processing, also suitable for non-ferrous and non-metal material cutting process. |

| YG546 | 14.55~14.75 | 90.5 | 2700 | High flexibility and high strength, withstand high impact load, suitable for stainless steel and cast iron rough processing |

| YG610 | 14.60~14.80 | 93.5 | 2000 | High wear resistance and high hardness, suitable for cast iron, high temperature alloy, quenched material cutting continuous and discontinuously. |

| YG640 | 13.10~13.30 | 91.5 | 2300 | Impact resistance and anti-oxidant, suitable for large cast piece cutting continuous and discontinuously, and anti-heat steel, high strength steel milling and digging. |

| YG643 | 13.60~13.80 | 93.3 | 1700 | High wear resistance, high anti-stick property, suitable for cast iron, high temperature cast iron, high temperature alloy, stainless steel, quenched steel and non-ferrous processing. |

| YG813 | 14.30~14.50 | 92 | 2200 | Good wear resistance, high bending strength resistance and anti-stick property, suitable for processing high temperature alloy, stainless steel and high Manganese steel and other material. |

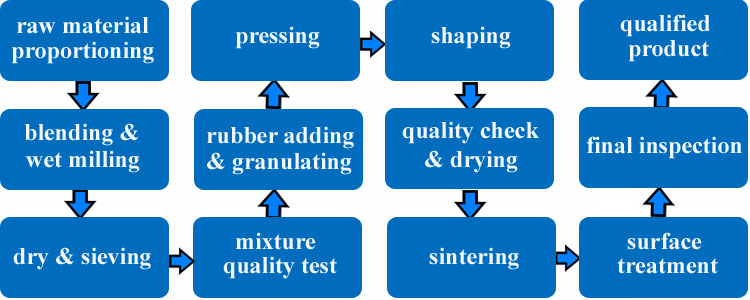

Production Process

Please leave message and we will get back to you ASAP!

Wechat : mayyang789