FOCUS ON TUNGSTEN CARBIDE PRODUCTS DEVELOPMENT/MANUFACTURE/PROCESS

| Availability: | |

|---|---|

| Quantity: | |

JDB9

Jinding

Product Description

Quick Detail

Product name: Cemented Tungsten Carbide Stamping Dies for Nuts

Customized support: OEM and ODM

Business type: Manufacturer

Advantage: 16 years experience

Material: 100% tungsten carbide

Size and Shape: OEM accepted

Shaping Mode: Forging Mould

Surface: Sand blasting , polishing , mirror surface

Shipment: By express, by air or by sea

Service: Best after-sales service

1. High wear resistance. Tungsten carbide cold heading dies material high wear resistance, tensile modulus can be guaranteed long-term work in any degree of deformation, ensuring standard size unchanged.

2. Excellent in polishing. Carbide has a good polishing, can be processed into the die hole mirror light, ensuring high quality standard surface.

3. Adhesion to metal is small. In the tungsten carbide cold heading process, ferrous metal material adhesion small carbide tooling materials, ensuring a high tungsten carbide cold heading die life.

4. The friction coefficient and energy consumption is small.

5. High thermal conductivity. Since the thermal conductivity of the tungsten carbide die is high, heat generated during the cold forging can quickly conducted away to improve the durability of the mold.

6. Good corrosion resistance.

Tungsten carbide cold heading mold has a wide usage, it often used for punching and stamping machine parts, drawing steel tubes and rods, impact-resistant forging die, hot forging die, finished rollers, nut wear resistant, impact resistant dies, nut forming die, high impact-resistant die or punching dies.

Recommended Grade

Product Specifications

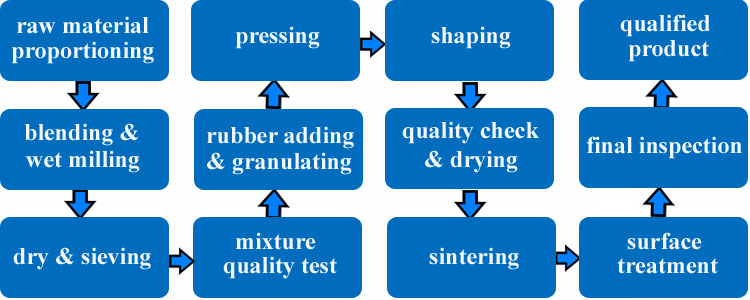

Production Process

Please leave message and we will get back to you ASAP!

Wechat : mayyang789