FOCUS ON TUNGSTEN CARBIDE PRODUCTS DEVELOPMENT/MANUFACTURE/PROCESS

| Availability: | |

|---|---|

| Quantity: | |

JDDF16

Jinding

Product Description

Quick Detail

Product name: Cemented Carbide Sandblast Boron Nozzle For Cleaning

Customized support: OEM and ODM

Material: 100% Virgin Tungsten Carbide

Grade: K01, K10, K20, K30, K40, etc.

Size: Standrad or OEM accepted

Color: Gray

Surface: Blank or sintering / polishing

Feature: Improved production rates and efficiencies

Product Application

1.The Boron Carbide Blasting Nozzle offer a longest life with optimum air and abrasive use.

2. The Boron Carbide blasting nozzles offer the greatest resistance to nozzle wear.

2. Its weight is similar to Silicon Carbide and is much lighter than Tungsten Carbide. Boron Carbide is far a superior.

Recommended Brand

Chinese Grade | Equal to ISO Category Number | chemical composition | Physical mechanical properties |

Application | |||||

WC | Co | Density | Bend Strength | Hardness | |||||

% | % | g/Cm3 | N/mm2 | HRA | |||||

YG3 | K01 | 96.5-97 | 3 | 14.9-15.3 | ≥1180 | ≥91.0 | It is suitable for the finishing of cast iron, non-ferrous metals, alloys and non-metallic materials, and semi-finishing vehicles for intermittent cutting. | ||

YG6X | K10 | 93.5 | 6 | 14.8-15.1 | ≥1420 | ≥92 | Finishing of chilled hard alloy cast iron and heat resistant alloy steel and ordinary cast iron | ||

YG6 | K20 | 94 | 6 | 14.7-15.1 | ≥1600 | ≥91 | Cast iron, non-ferrous metals and alloys, non-metallic materials, medium to cutting, semi-finishing and finishing. | ||

YG8 | K20-K30 | 92 | 8 | 14.5-14.9 | ≥1600 | ≥90 | Suitable for casting of cast iron, non-ferrous metals and their alloys and non-metallic materials. | ||

YG10 | K40 | 90 | 10 | 14.3-14.7 | ≥1900 | ≥89 | It is used for large batch production and has excellent strength and toughness. | ||

YG10X | K40 | 89 | 10 | 14.3-14.7 | ≥2200 | ≥89.5 | Suitable for small diameter micro drills, end mills, rotary boring tools, etc. | ||

YG15 | K30 | 85 | 15 | 13.9-14.2 | ≥2100 | ≥87 | Forging, perforating and stamping tools for steel bars and steel tubes with high compression ratios and working under large stresses | ||

YG20 | K30 | 80 | 20 | 13.4-13.7 | ≥2500 | ≥85.5 | Stamping die, stamping watch parts, musical instrument spring piece; | ||

YG20C | K40 | 80 | 20 | 13.4-13.7 | ≥2200 | ≥82 | Production of standard parts, bearings, tools and other industries for cold heading, cold punching, cold pressing die, warhead to the shell of the stamping die | ||

YG30 | 70 | 30 | 12.75 | ≥2500 | ≥82.8 | High toughness | |||

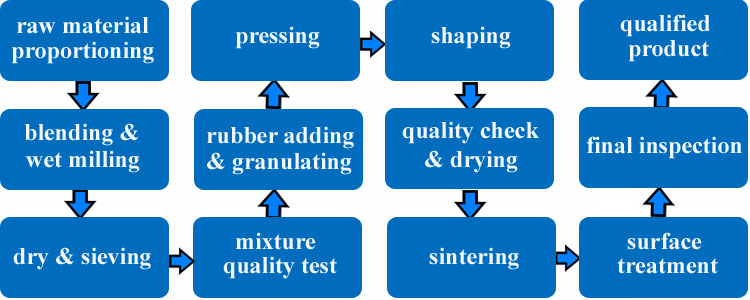

Production Process

Please leave message and we will get back to you ASAP!

Wechat : mayyang789